Parking brake, gearbox, 4×4 engagement and disengagement: while these functions are mainly mechanical today, they will be electrified over the coming years. EFI Automotive remains at the forefront of this change with Greenshift, a new generation of compact, intelligent and connected actuators. Presentation.

But why would you electrify functions that have proven their worth in mechanical form over decades of use? For at least three reasons. Firstly, manufacturers rely on intelligent drivetrain control to improve their efficiency. Why? To reduce fuel consumption and pollutant emissions for internal combustion engines. And to increase the range of hybrid and electric vehicles.

Electrified transmissions: a market set to increase fivefold by 2030

The second objective is to collect operating data for use in diagnostics or preventive maintenance. A cable, a gear, a gearshift: these parts do not provide data. To collect data, you need electric actuators.

And finally, electrification opens up new possibilities for the interior design. Replace the parking brake and gearshift with buttons, joysticks or a rotating dial to create a decluttered, comfortable space, with everything in easy reach of the driver.

“Transmission electrification should increase by 21% each year between now and 2030, that is a fivefold increase in the market,” adds Philippe Grebert, Strategic Product Line Manager. “Our first mass-produced electric actuator dates back to 2013 and was fitted to an engine cooling circuit. Since 2020, we have targeted developments in transmission products.”

Mass-production launch for Greenshift at end 2021

A number of projects based around this new range, named Greenshift, have been approved. They involve a European manufacturer and a number of major global players, with mass-production planned, depending on circumstances, between end 2021 and 2024. Greenshift actuators target three applications: the parking brake or park-lock, disengaging 4×4 and one of the hybrid vehicle propulsion systems (disconnect), and changing gear (shift by wire and gear shifting).

As explained earlier, the park-lock uses an electric actuator instead of a lever that sends a mechanical force through a cable. However, this actuator is certainly not a basic component: “If, for, example a vehicle is parked on a gradient, the park-lock is put in tension and a considerable force is required to release this and move forward,” illustrates Philippe Grebert. “This is why the logic that controls the actuator motor adapts at each step of the journey.” This is an excellent example of the concept of ‘intelligent control’.

The disconnect function reduces losses due to friction in order to improve vehicle efficiency. It is found on vehicles with disengageable 4×4 transmission and on hybrid and electric vehicles to disconnect the unused part of the powertrain. It ensures that the kilowatts generated are solely used to power the driving wheels. “The efficiency gain can range from 1% to 5%. Moreover, manufacturers are hunting down CO2 emissions; remember that Europe now applies heavy financial sanctions when they exceed an average of 95 grams of CO2 per km across their whole range.”

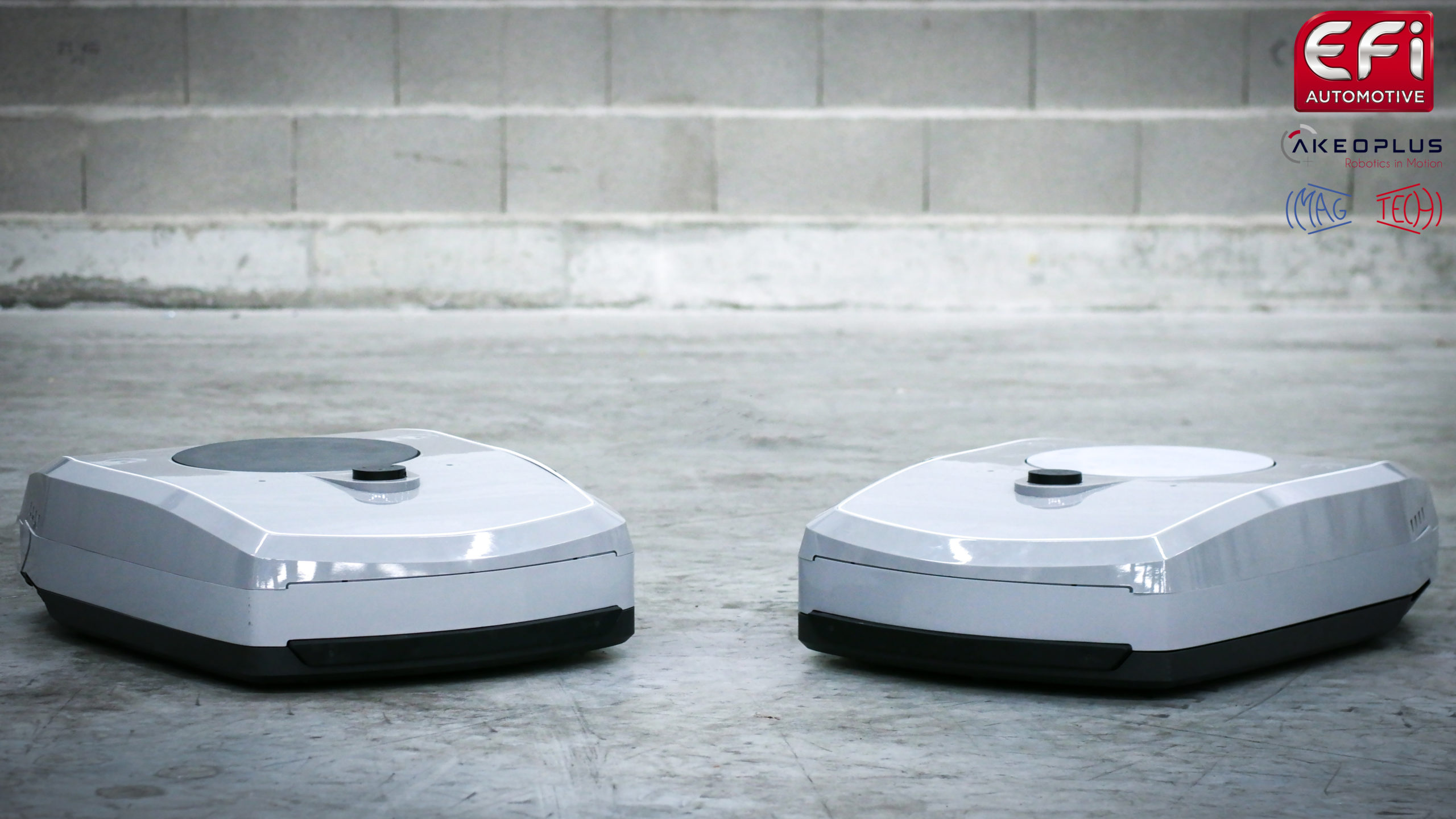

All-in-one, compact, light actuators

Gear changes are electrified with shift by wire and gear shifting, through the driver controls (by replacing the gearshift) and through the forks that enable the shift from one group of gears to another, respectively. “The two functions are intended for automatic gearboxes. In the long term, they could also be fitted to electric vehicles, for which we are starting to talk about two-speed gearboxes. It should, in time, become possible to optimize the gear ratio and the motor operating point depending on the required torque.”

To make an impact in these markets, the Greenshift range is counting on the advanced integration of its actuators. Instead of a worm and a worm wheel, they use inline, concentric gears, which guarantee compact size and transmission efficiency. The actuator position sensor, with inductive technology, is not sensitive to electromagnetic disturbances and can be placed in the actuator: just one part to fix in place and connect instead of two. “Our products have a more consistent size than their competitors. They are also lighter,” emphasizes Philippe Grebert.

Robust operation in all conditions

Operating robustness is their second advantage. Greenshift actuators are equipped with brushless motors, controlled by a logic that regulates the power level using the speed of rotation and not torque; their response time is therefore optimized. The overall design, characterized by predictive simulation, assures their performance, constant in all stress levels and temperature conditions. The products comply with ASIL C as defined by ISO 26262, which confirms their operating reliability.

Finally, these intelligent actuators can be connected to the vehicle’s CAN bus to send data and alerts, for example if their current and charge level deviates too often from the benchmark values. “We already offer basic diagnostics on our key products. But we can go much further, particularly by sending preventive maintenance data to fleet managers,” concludes Philippe Grebert.